Filtration for the EGCS scrubber systems

This reduction will abate the airborne emissions of sulphur oxides (SOx) and other particulates that are very harmful for the environment and humans.

In order to comply with this regulation, all the ships operating outside Emission Control Areas (ECA) must use fuel oil that contains maximum 0.5% of sulphur oxide. Meanwhile for the vessels operating inside the EAC area the limit is set at 0.1%.

Otherwise the ship owners can keep the HFO (heavy fuel oil) system that are largely installed and used and abate the emissions throughout systems that treat the exhaust gas (Exhaust Gas Cleaning System-EGCS) or most known as scrubber.

In this manner the sulphur oxides are largely reduced, due to two distinct processes: one is the dissolving of the SOx in the water droplets and the other is the reaction between the alkaline substances (naturally present in the sea water) and the dissolved SOx.

Both for open and close loop Scrubber system the water used has to be filtrated. In the open loop system, the quantity of water used is very substantial (arriving at 1400m3/h).

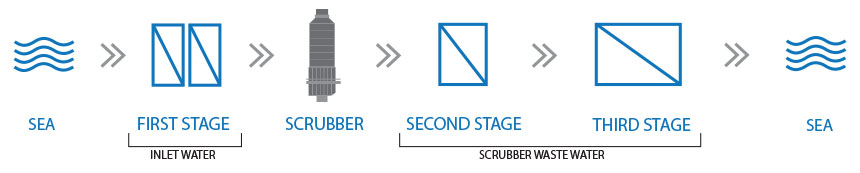

Alfa Water has developed huge experience in this sector and is able to provide solutions for the different phases of the water usage in the scrubber filtration:

a. Prefiltration of the feed water for the scrubber: our SAF 2205 (DUPLEX) filters protect the spray nozzles;

b. Filtration of the wash water from the scrubber that prevents the release of contaminant suspended solids in the sea. After the sulphur combustion takes place the discharged water becomes acidic (pH 2-3) and the content of oil, heavy metals, IPA and hydrocarbons reaches very high level. Filters in SMO 254 are used for this application.

c. For the storage and the treatment of the water used in the filtration process (pos b.) we propose the multibag filters in GRP or polyethylene, or the complete system ABF Vacuum Band Filter.

d. Polishing unit – at the filter drain, the AMT automatic magnetic filter in SMO 254 attracts the heavy metals present in the water.

Alfa Water systems developed specifically for the pos. a, b, c & d the water discharged from the scrubber is in compliance with the regulations in all three versions of the ECGS technology, i.e. open loop, closed loop and hybrid.

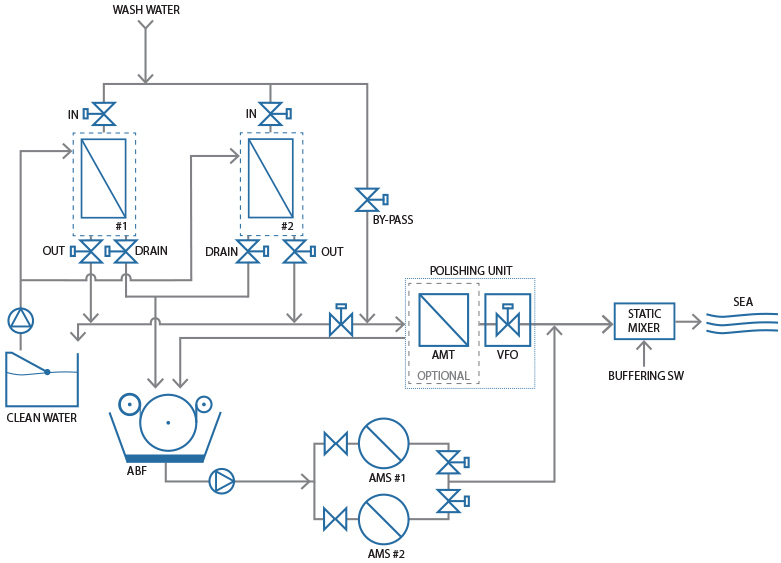

Application schemes

# 1 and # 2:

Filters that can be used in this stage

- INFILT

- ABR 170

- AVC 160

ABF: Vacuum band filter

AMS: Multibag filter

AMT: Magnetic trap

VFO: Variable flow orifice

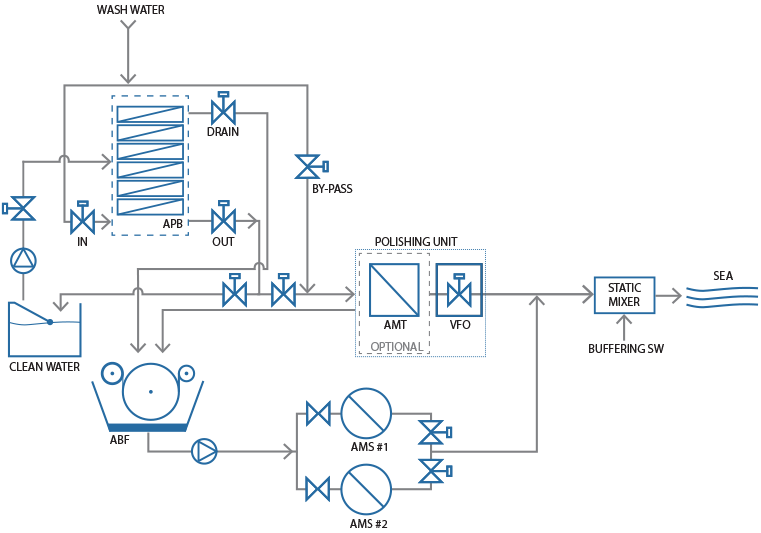

#1:

Filters that can be used in this stage

- INFILT

- ABR 170

- AVC 160

ABF: Vacuum band filter

AMS: Multibag filter

AMT: Magnetic trap

VFO: Variable flow orifice

APB: Pressurized battery of AVC filter in GRP

AMS: Multibag filter

AMT: Magnetic trap

VFO: Variable flow orifice